Nondestructive testing of pipeline products

Nondestructive testing (NDT) is a testing method for testing or evaluating discontinuities or characteristic differences in materials,components or assemblies without damaging steel tubes,butt welded pipe fittings,forged pipe fittings,malleable iron pipe fittings or flanges.This means that the product can still be used after inspection or testing.Compared to NDT,other tests are destructive in nature and can only be used for some samples that will not be used as finished products in the project.

Types of nondestructive testing used for pipeline products:

Conventional nondestructive testing methods used for pipeline products include Radiographic Testing(RT),Ultrasonic Testing (UT),Magnetic particle Testing (MT) and Penetrant Testing(PT).In addition,there are some nondestructive testing methods,such as Eddy Current Testing (ET),Acoustic Emission Testing (AE) and other methods.

These four methods are the most commonly used nondestructive testing methods in manufacturing quality inspection and in-service inspection for pressure-bearing steel tubes,fittings and flanges.The radiographic testing(RT) and the ultrasonic testing (UT) are mainly used to detect internal defects in time.The magnetic particle testing (MT) and the penetrant testing (PT) are mainly used to detect surface defects in time.

Radiographic Testing:

Radiographic testing(RT or X-ray or Gamma ray)is a non-destructive testing (NDT) method that involves the use of either x-rays or gamma rays to view the internal structure of a component.Radiographic testing is often used for the weld detection of pipeline products,such as weld of steel pipe,elbow,tee,flange etc.The obvious advantage of the X-ray method is that it can help establish the internal integrity of the weld without damaging the welded parts.

Ultrasonic testing for large diameter elbow weld

Ultrasonic Testing:

Ultrasonic nondestructive testing,also known as ultrasonic testing or simply UT,is a method of characterizing the thickness or internal structure of a test piece through the use of high frequency sound waves.The frequencies,or pitch,used for ultrasonic testing are many times higher than the limit of human hearing,most commonly in the range from 500 KHz to 20 MHz.Ultrasonic testing devices pass ultrasonic sound waves into the test piece and measure the waves that reflect back to the device.The profile of the reflection is interpreted by software and the human operator to determine if the test piece is within spec.

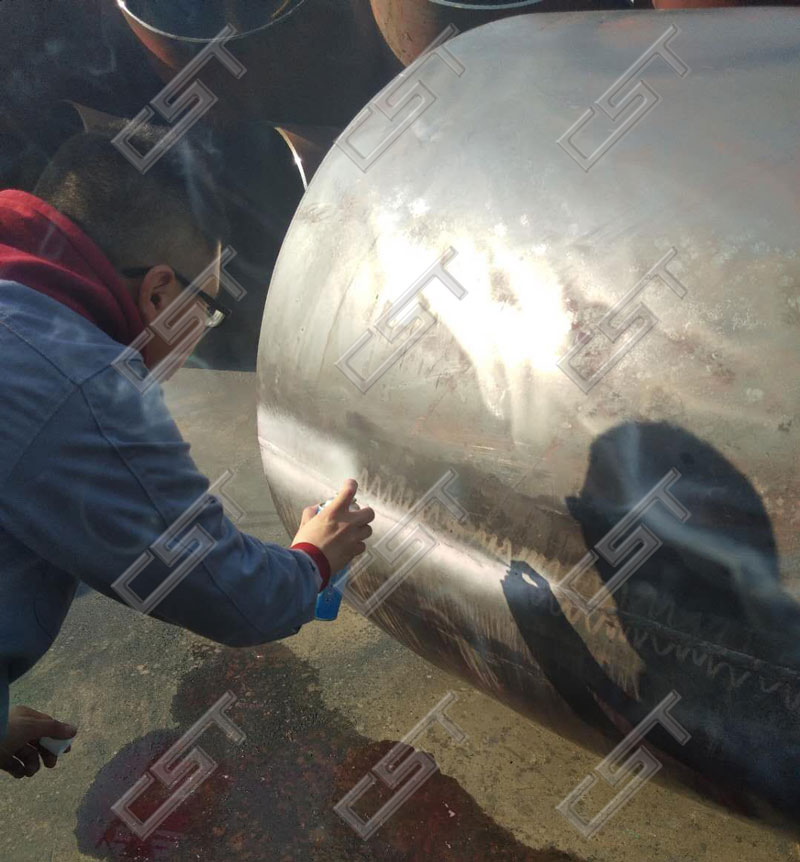

Magnetic particle testing for large size 90 degree elbow

Magnetic particle Testing:

Magnetic particle testing(MT),also referred to as magnetic particle inspection(MPI),it is used to detect surface and slightly subsurface flaws in most ferromagnetic materials such as iron, nickel,and cobalt,and some of their alloys.Because it does not necessitate the degree of surface preparation required by other nondestructive test methods,conducting MT is relatively fast nd easy.This has made it one of the more commonly utilized NDT techniques.

Penetrant testing for large diameter 90 degree elbow weld

Penetrant Testing:

Penetrant testing(PT),also called dye penetrant inspection(DPI) or liquid penetrant inspection(LPI).Penetrant solution is applied to pipe fittings or flanges cleaned surfaces.The liquid is pulled into cracks or defects by capillary action.Excess penetrant material is carefully cleaned from the surface.A developer is applied to pull the trapped penetrant material back to the surface where it is spread out and shows an indication.This indication is much easier to find than the crack or defect.

Eddy Current Testing

The eddy current testing is used a lot as the NDT method for seamless steel pipes.Alternating electrical current is passed through a steel pipe producing a magnetic field.When the pipe is placed closed to a conductive material,the changing magnetic field induces current flow in the pipe.These currents travel in closed loops and are called eddy currents.Eddy currents produce their own magnetic field that can be measured and used to find flaws.

Cangzhou steel pipe & fitting CO.,LTD ,our team has more than 20 years experiences for professional manufacturing and supplying of piping system products,like steel pipes,butt weld pipe fittings,forged steel pipe fittings,malleable iron pipe fittings and steel flanges and other relevant piping solutions.Our quality inspection department can do all kinds of nondestructive testing and destructive testing for customers’ requirements.If you want to know more about our products,please email us:goodsteelpipes@hotmail.com